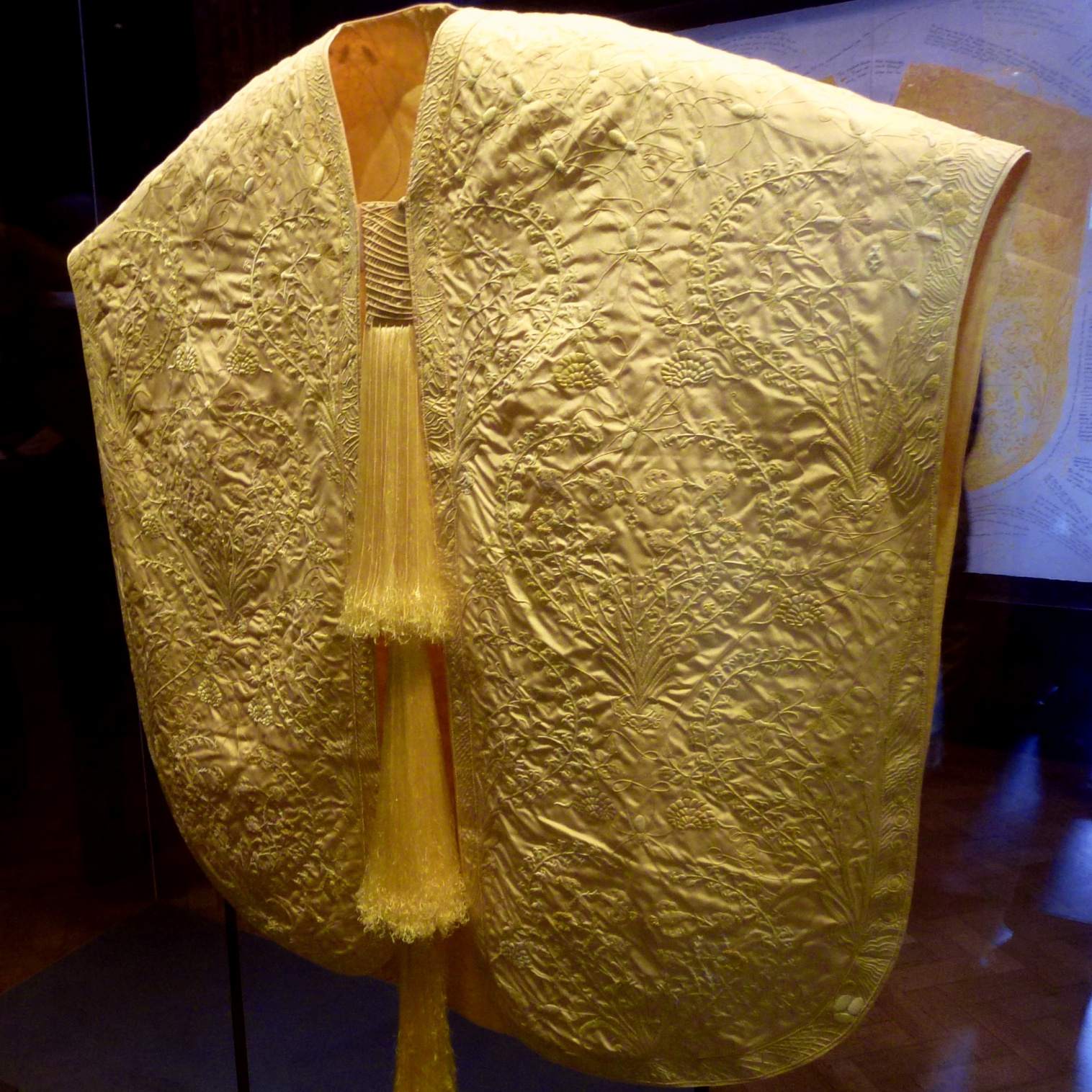

In 2009, what is believed to be the world’s largest and rarest piece of cloth made entirely from the silk of the golden silk orb-weaver was exhibited at the American Museum of Natural History in New York. It is said to be the “only large piece of cloth made from natural spider silk existing in the world today.” It is a breathtaking textile and the story of its creation is fascinating.

This piece of cloth was a project led jointly by Simon Peers, a British art historian who specializes in textiles, and Nicholas Godley, his American business partner. The project took five years to complete and cost over £300,000 (approximately $395820). The result of this endeavor was a 3.4-meter (11.2 ft/) by 1.2-meter (3.9 ft.) piece of textile.

The inspiration for a spider web silk masterpiece

The cloth produced by Peers and Godley is a gold-colored brocaded shawl/cape. The inspiration for this masterpiece was drawn by Peers from a French account dating to the 19th century. The account describes the attempt of a French Jesuit missionary by the name of Father Paul Camboué to extract and making fabrics from spider silk. Whilst various attempts have been made in the past to turn spider silk into fabric, Father Camboué is regarded as the first person who succeeded in doing so. Nonetheless, spider web had already been harvested in ancient times for different purposes. The ancient Greeks, for instance, used spider web to stop wounds from bleeding.

As a missionary in Madagascar, Father Camboué utilized a species of spiders found on the island to produce his spider web silk. Together with a business partner by the name of M. Nogué, a spider silk fabric industry was established on the island and one of their products, “a complete set of bed hangings” was even exhibited at the Paris Exposition of 1898. The work of the two Frenchmen has since been lost. Nevertheless, it received some attention at that time and provided inspiration for Peers and Godley’s undertaking about a century later.

Catching and extracting the spider silk

One of the important things in Camboué and Nogué’s production of spider silk is a device invented by the latter to extract the silk. This small machine was hand-driven and was capable of extracting silk from up to 24 spiders simultaneously without hurting them. Peers managed to build a replica of this machine, and the ‘spider-silking’ process could begin.

Before this, however, the spiders had to be caught. The spider used by Peers and Godley to produce their cloth is known as the red-legged golden orb-web spider (Nephila inaurata), which is a species native to Eastern and South-eastern Africa, as well as several islands in the Western Indian Ocean, including Madagascar. Only the females of this species produce the silk, which they weave into webs. The webs glow in the sunlight and it has been suggested that this is meant either to attract prey, or to serve as a camouflage.

For Peers and Godley, as many as a million of these female red-legged golden orb-web spiders had to be captured in order to acquire enough silk for their shawl / cape. Fortunately, this is a common species of spider and it is abundant on the island. The spiders were returned to the wild once they ran out of silk. After a week, however, the spiders could generate silk once more. The spiders only produce their silk during the rainy season, so they were only caught during the months between October and June.

At the end of four years, a golden-colored shawl / cape was produced. It went on display first at the American Museum of Natural History in New York and then at the Victoria and Albert Museum in London. This piece of work proved that spider silk could indeed be used to make fabrics.

Difficulty in spider silk production

Nevertheless, it is not an easy product to mass produce. When housed together, for example, these spiders tend to turn into cannibals. Still, spider silk has been found to be extremely strong, yet light and flexible, a property that intrigues many scientists. Therefore, researchers have been trying to obtain this silk by other means.

One, for instance, is to insert the spider genes into other organisms (such as bacteria, though some have tried it on cows and goats), and then to harvest the silk from them. Such attempts have only been moderately successful. It seems that for the time being, one would still need to catch a great number of spiders if one wishes to produce a piece of fabric from its silk.